Products

YAWATA H-450R (For Metal to Metal & Sand Abrasion)

Classification : DIN 8555 : E 1-UM-350

Approvals : TIS

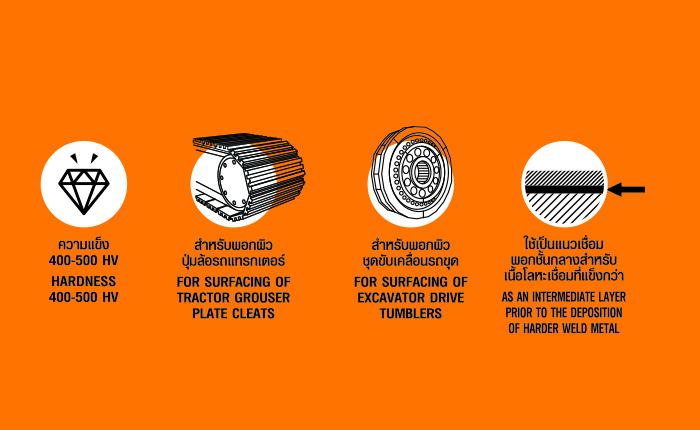

Applications : Surfacing of tractor grouser plate cleats, ecavator drive tumblers, steel mill wobbler ends and coupling boxes, clipping tools and as an intermediate layer prior to the deposition of harder weld metal.

YAWATA H-450R is a rutile coated hardfacing electrode depositing alloyed weld metal with approximately 450 Vickers hardness which for many applications can be applied directly on hardenable steels. Particularly suitable for the reclamation and fabrication of new metal cutting or forming equipment.

DIN 8555 : E 1-UM-450

|

C

|

Si

|

Mn

|

Cr

|

Cr+Mn+Mo+Ni

|

|

|

Req.

|

≤0.40

|

N.S.

|

N.S.

|

N.S.

|

≤5.0

|

|

Typ.

|

0.29

|

0.49

|

0.70

|

2.30

|

3.20

|

Typ. = Typical results

N.S. = Not Specified

|

Vicker(Hv)

|

(As-welded)

|

|

440

|

Single layer

|

|

470

|

Multiple layer

|

| Diameter /Length (mm) |

3.2/350 | 4.0/400 | 5.0/450 | |

| Welding position | Current (A) | |||

| V | 90-125 | 140-180 | 170-240 | |

| F | 90-115 | 120-150 | - | |

Use dry electrodes only. Damp electrodes should be re-dried at 70~120℃ for 60 minutes before use.