Products

YAWATA L-55W (For 490N/mm2 High Tensile Strength Steel)

Classification : AWS A 5.1 : E7016, EN 499 : E42 2 B 1 2 H5

Approvals : ABS, TIS

Application : One side welding of pipes and general welding of 490 N/mm high tensile strength steels for ships, and pressure vessels.

WHY STRONGER THAN EVER?:

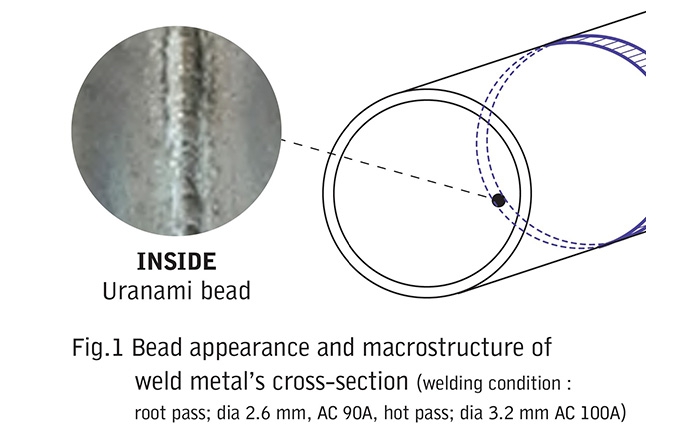

- Due to its improved arc direction and arc stability, New YAWATA L-55W is excellent Uranami welding (one side welding)

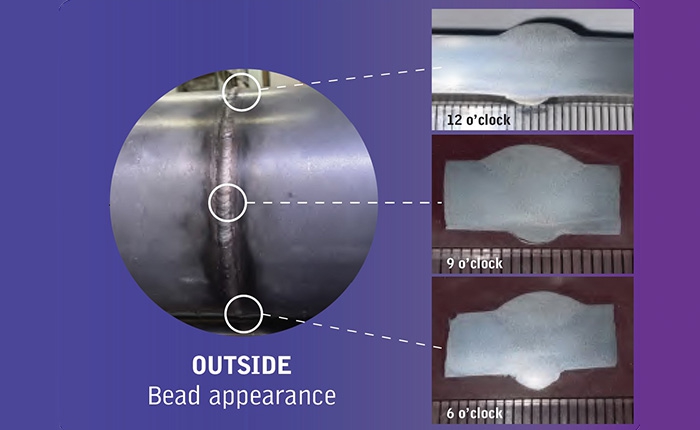

- The arc is stable, strong and gives a sound penetration, so the bead appearance is beautiful and good Uranami bead can be obtained in every position welding

- Uranami welding is Ok if you keep the keyhole constant while checking the sound of the arc passing through the back of the groove

YAWATA L-55W is a low hydrogen type electrode for one side welding in all positions. In low current range in root pass welding of pipes, a sound penetration bead free from blowholes is obtained due to stable arc, strong arc force, and excellent slag fluidity and coverage.

AWS A 5.1 : E7016

EN 499 : E42 2 B 1 2 H5

EN 499 : E42 2 B 1 2 H5

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

V

|

C.L.

|

|

|

Req.

|

≤0.15

|

≤0.75

|

≤1.60

|

≤0.035

|

≤0.035

|

≤0.20

|

≤0.30

|

≤0.30

|

≤0.08

|

≤1.75

|

|

Typ.

|

0.07

|

0.63

|

1.20

|

0.010

|

0.011

|

0.11

|

≤0.01

|

0.07

|

≤0.01

|

1.40

|

Typ. = Typical results

N.S. = Not Specified

C.L. = Combined Limit for Mn + Ni + Cr + Mo + V

| Tensile Strength N/mm2 (kgf/mm2) |

Yield Strength N/mm2 (kgf/mm2) |

Elongation % |

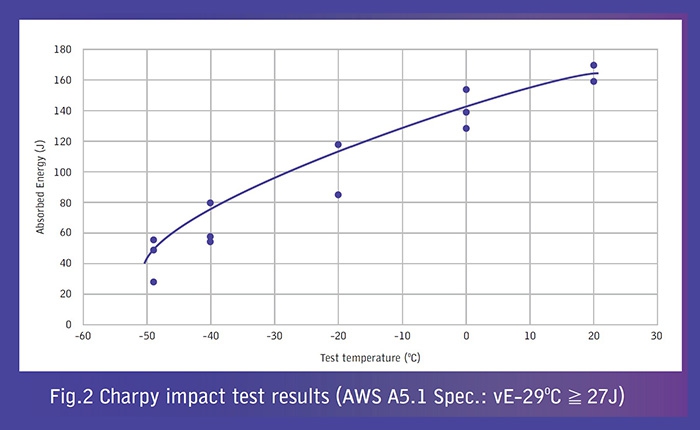

Charpy 2V-notch ที่ -49oC, J (kgf.m) |

Diffusible H2 Content |

|

| Req. | ≥430 (42) | ≥430 (42) | ≥17 | -29oC/-30oC = ≥27 (AWS A5.1) -29oC/-30oC = ≥47 (ISO 2560-A) -49oC/-50oC = ≥47 (ISO 2560-A) |

≤ 10 ml/100g |

| Typ. | 580 (59) | 500 (51) | ≥31 | @ -49oC, 120 (10.4) | ≤ 5 ml/100g |

| Diameter /Length (mm) |

2.6/300 | 3.2/350 | 4.0/400 | 5.0/450 |

| Welding Position | Current (A) | |||

| F | 50-100 | 90-140 | 120-180 | 160-220 |

| V, OH | 40-80 | 80-120 | 100-160 | 154-200 |

| One Side Welding | 40-80 | 60-110 | 80-140 | - |

1. Use dry electrodes only. Damp electrodes should be re-dried at 300~350℃ for 60 minutes before use.

2. DC (-) should be used for one side welding.

3. 3.2 mm. diameter electrode is recommended for all positions welding of pipes with 6~15 mm. wall thickness.

4. Arc should started on a small plate or the side of the groove and cut after moving crater to the side of the groove.

2. DC (-) should be used for one side welding.

3. 3.2 mm. diameter electrode is recommended for all positions welding of pipes with 6~15 mm. wall thickness.

4. Arc should started on a small plate or the side of the groove and cut after moving crater to the side of the groove.