Products

YAWATA L-55┬Ā(For 490N/mm2┬ĀHigh Tensile Strength Steel)

Classification :┬ĀAWS A 5.1 : E7016,┬Ā JIS Z 3211 : E4916U

Approvals :┬ĀABS, BV, DNV, LR, NK, TIS

Application :┬ĀWelding of 490 N/mm2┬Āhigh tensile strength steels for ships, structures and bridges.

PDFYawata-Pamphlet-L55 .pdf┬Ā

YAWATA L-55 is a low hydrogen type electrode for all positions welding. Deposited metal┬Āshows excellent crack resistance, mechanical properties and X-ray quality. Vertical and┬Āoverhead welding are very easy.

AWS A 5.1 : E7016

JIS Z 3211 : E4916U

DIN 1913 : E 51 3 3 B(R) 10

EN 499 : E 42 2 B 12 H5

| ┬Ā |

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

V

|

C.L.

|

|

Req.┬Ā ┬Ā┬Ā

|

Ōēż0.15

|

Ōēż0.75

|

Ōēż1.60

|

Ōēż0.035

|

Ōēż0.035

|

Ōēż0.20

|

Ōēż0.30

|

Ōēż0.30

|

Ōēż0.08

|

Ōēż1.75

|

|

Typ.┬Ā ┬Ā┬Ā

|

0.08

|

0.54

|

1.10

|

0.007

|

0.009

|

0.09

|

Ōēż0.01

|

0.09

|

Ōēż0.01

|

1.10

|

Typ. = Typical results

N.S. = Not Specified

C.L. = Combined Limit for Mn + Ni + Cr + Mo + V

┬Ā

| ┬Ā | Tensile Strength N/mm2 (kgf/mm2) |

Yield Strength N/mm2 (kgf/mm2) |

Elongation % |

Charpy┬Ā 2V-notch ÓĖŚÓĖĄÓ╣ł -49oC, J (kgf.m) |

Diffusible H2 Content ┬Ā |

| Req.┬Ā ┬Ā | Ōēź430 (42) | Ōēź430 (42) | Ōēź17 | -20oC=┬ĀŌēź27┬Ā┬Ā(AWS A5.1) -29oC/-30oC┬Ā=┬ĀŌēź27┬Ā┬Ā(AWS A5.1) -29oC/-30oC┬Ā=┬ĀŌēź47┬Ā┬Ā(ISO 2560-A) -49oC/-50oC┬Ā=┬ĀŌēź47┬Ā┬Ā(ISO 2560-A) |

Ōēż 10 ml/100g |

| Typ.┬Ā ┬Ā | 550 (56) | 480 (49) | Ōēź32 | @ -20oC,┬ĀŌēź 170 (17.3) | ┬ĀŌēż 5 ml/100g |

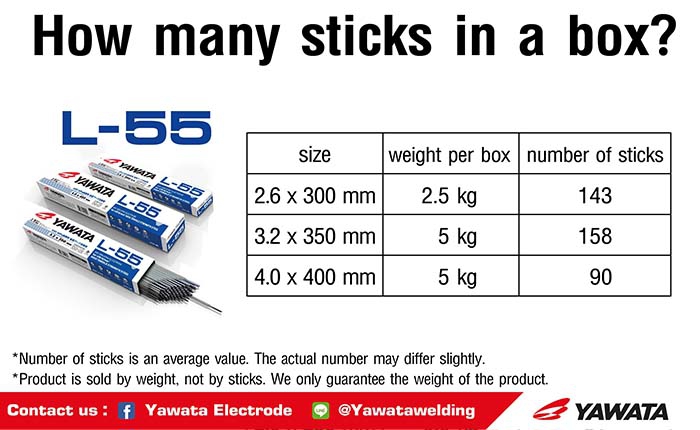

| Diameter/ Length (mm) |

2.6/300 | 3.2/350 | 4.0/400 | 5.0/450 |

| Welding Position | Current (A) | |||

| F | 70-10 | 100-140 | 150-190 | 190-240 |

| V-up, OH | 60-90 | 80-120 | 110-150 | 130-170 |

1. Use dry electrodes only.┬Ā Damp┬Ā electrodes should be re-dried at┬Ā 300’Į×350Ōäā┬Ā for 60┬Āminutes.

2. Backstep method should be applied to prevent blowholes and pits at arc starting and arc┬Ālength should be kept as short as possible during welding.

3. All water, rust and oil in groove should be completely removed to prevent cracks and┬Āblowholes.

2. Backstep method should be applied to prevent blowholes and pits at arc starting and arc┬Ālength should be kept as short as possible during welding.

3. All water, rust and oil in groove should be completely removed to prevent cracks and┬Āblowholes.