Products

YAWATA H-350C (For Metal to Metal & Sand Abrasion)

Classification : DIN 8555 : E 1-UM-350

Approvals : TIS

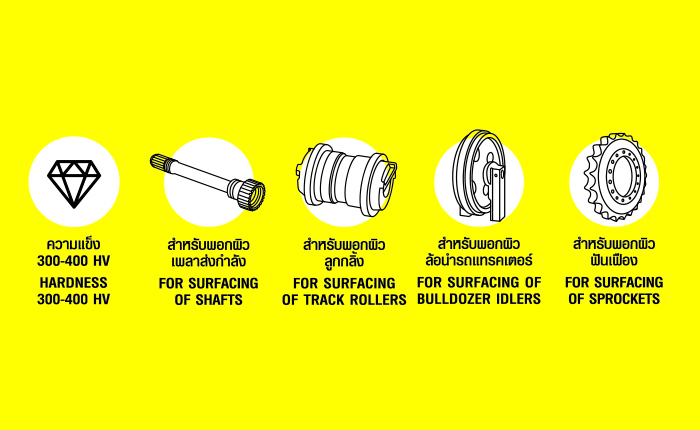

Applications : Surfacing of shafts, rollers and bulldozer idlers and sprockets.

YAWATA H-350C is a low hydrogen type electrode for surfacing worn machine parts subjected to high stress abrasion by metal to metal sliding or rolling. Deposited metal of about 350 Vickers hardness as welded provides reasonable abrasion resistance and is machinable in general.

DIN 8555 : E 1-UM-350

|

C

|

Si

|

Mn

|

Cr

|

Cr+Mn+Mo+Ni

|

|

|

Req.

|

≤0.40

|

N.S.

|

N.S.

|

N.S.

|

≤5.0

|

|

Typ.

|

0.18

|

0.29

|

1.12

|

1.35

|

3.04

|

Typ. = Typical results

N.S. = Not Specified

|

Vicker(Hv)

|

Rockwell C (HRC)

|

Shore

|

Heat Treatment

|

|

356

|

36

|

49

|

As welded; preheat, interpass 150๐C

|

|

323

|

32

|

45

|

As welded; preheat, interpass 300๐C

|

|

336

|

34

|

47

|

Tempered at 500๐C

|

|

301

|

30

|

42

|

Tempered at 600๐C

|

|

439

|

44

|

58

|

Water quenched at 950๐C

|

| Diameter /Length (mm) |

3.2/350 | 4.0/400 | 5.0/450 | |

| Welding position | Current (A) | |||

| V | 100-150 | 140-180 | 170-240 | |

| F | 80-120 | 110-170 | - | |

1. Use dry electrodes only. Damp electrodes should be re-dried at 300~350℃ for 60 minutes before use.

2. Preheating at more than 150℃ is required to surface low alloy steels, high carbon steels, etc.

2. Preheating at more than 150℃ is required to surface low alloy steels, high carbon steels, etc.