Products

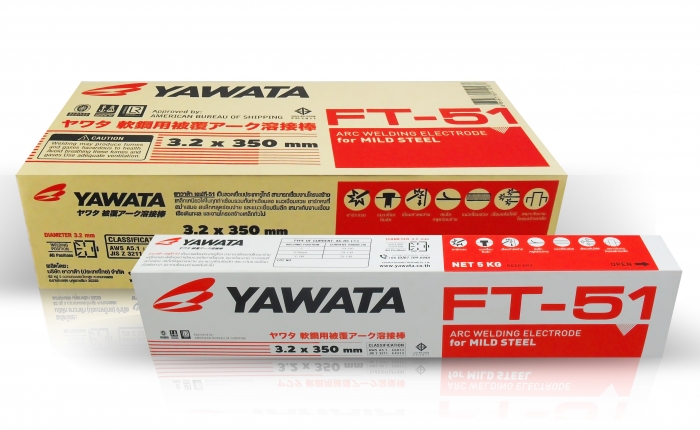

YAWATA FT-51 (For Mild Steel)

YAWATA FT-51 now comes in small and economical-to-use size. The 15-piece vacuum pack will make sure that nothing goes to waste. It is a DIY favourite!!Classification : AWS A 5.1 : E6013, JIS Z 3211 : E4313

Approvals : ABS, BV, DNV GL, LR, TIS

Applications : Welding of mild steel sheet for ships, rolling-stocks, structures, and finished welding of heavy structural works.

PDFYawata-Pamphlet-FT51.pdf

YAWATA FT-51 is a high rutile type electrode for all positions welding and assures easy operation even in vertical downward position. Spatters are less and bead appearance is beautiful.

AWS A 5.1 : E6013

JIS Z 3211 : E4313

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

V

|

C.L.

|

|

|

Req.

|

≤0.20

|

≤1.00

|

≤1.20

|

N.S.

|

N.S.

|

≤0.20

|

≤0.30

|

≤0.30

|

≤0.08

|

N.S.

|

|

Typ.

|

0.09

|

0.34

|

0.40

|

0.013

|

0.011

|

0.06

|

0.01

|

0.06

|

0.02

|

0.50

|

Typ. = Typical results

N.S. = Not Specified

C.L. = Combined Limit for Mn + Ni + Cr + Mo + V

| Tensile Strength N/mm2 (kgf/mm2) |

Yield Strength N/mm2 (kgf/mm2) |

Elongation % |

Charpy 2V-notch at 0๐C, J (kgf.m) |

|

| Req. | ≥430 (42) | ≥430 (42) | ≥17 | N.S. (AWS A5.1) ≥47 (ISO 2560-A) |

| Typ. | 510 | 460 | 28 | 60 |

| Diameter/Length (mm) | 1.6/250 | 2.0/300 | 2.6/350 | 3.2/350 | 4.0/4000 | 5.0/400 |

| Welding position | Current (A) | |||||

| F | 20-50 | 30-70 | 50-100 | 70-130 | 110-180 | 140-220 |

| V-down | 20-50 | 30-70 | 50-100 | 70-130 | 110-180 | 150-220 |

| V, OH | 20-50 | 30-70 | 50-100 | 70-130 | 100-150 | 130-190 |

1. Use dry electrodes only.

2. If coating flux absorbs excessive moisture, arc and slag fluidity become unstable, spatters increase , undercuts and blowholes are apt to occur. Damp electrodes should be re-dried at 70~120℃ for 60 minutes.

3. For inclined and vertical downward positions , touch electrode tip lightly to the base metal and deposit a stringer bead with electrode slope 40~80°.

2. If coating flux absorbs excessive moisture, arc and slag fluidity become unstable, spatters increase , undercuts and blowholes are apt to occur. Damp electrodes should be re-dried at 70~120℃ for 60 minutes.

3. For inclined and vertical downward positions , touch electrode tip lightly to the base metal and deposit a stringer bead with electrode slope 40~80°.