Products

YAWATA 308L-16Â

(For Low Carbon 18%Cr-8%Ni Stainless Steel)

Classification : AWS A 5.4 : E308L-16, JIS Z 3221 : ES308L-16, DIN 8556 : E 19 9 LR 26

Approvals :Â ABS, TIS

Application :Â Welding of all Cr-Ni steels with low or medium C content, as well as titamium and niobium stabilized Cr-Ni steels of the 18%Cr-8%Ni type, e.g. material DIN No 1.4300, 1.4301, 1.4306, 1.4541, 1.4543, 1.4550, AISI 302, 304, 304L, 321, 347.

PDFYawata-Pamphlet-Stainless.pdf

Â

YAWATA 308L-16 is a rutile high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized Cr-Ni steels resistant to atmospheric corrosion of the 18%Cr-8%Ni type. Re-sistant to grain disintegration of operating temperatures up to 350℃. Smooth running, good striking and restriking, regular appearance, finely rippled, smooth junction, easy slag removal.

| Â |

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Ni

|

Mo

|

Cu

|

|

Req.  Â

|

≤0.04

|

≤1.00

|

0.5-2.5

|

≤0.040

|

≤0.030

|

18.0-21.0

|

9.0-11.0

|

≤0.75

|

≤0.75

|

|

Typ.  Â

|

0.03

|

0.80

|

1.1

|

0.028

|

0.018

|

20.1

|

9.3

|

0.14

|

0.13

|

Typ. = Typical results

N.S. = Not Specified

Â

| Â | Tensile Stregth N/mm2Â (kgf/mm2) |

Elongation % |

Creep-rupture strength (as welded, 650ºC x 1000h N/mm2) |

| Req.   | ≥520 | ≥30 | ≥120 |

| Typ.   | 560 | 51 | 120 |

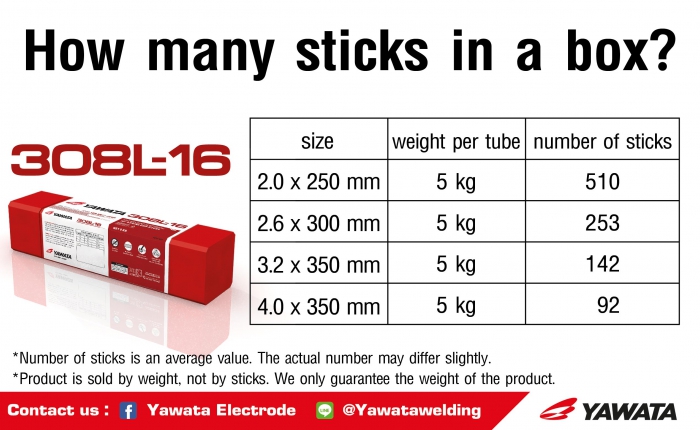

| Diameter /Length (mm) |

2.0/250 | 2.6/300 | 3.2/350 | 4.0/350 | 5.0/350 |

| Welding Position | Current (A) | ||||

| F | 40-50 | 55-70 | 80-100 | 110-140 | 140-170 |

| V, OH | 35-45 | 45-65 | 70-90 | 100-130 | - |

2. Dirt such as oil, grease and dust should be completely removed from groove.

3. Excessively wide weaving may cause welding defects. Keep weaving width to less than 2.5 times electrodes diameter.